The AirFLEX® has evolved into a tougher and more resilient machine, all while maintaining its simple design and providing the closest cut imaginable. With improvements that enhance performance and reliability, the NXT focuses on the future of farming.

AirFLEX NXT Lightweight, fast and built to last

Still the closest shave

Fully flexible cutterbar controlled by air

The independently-suspended cutterbar is light, fast-reacting, and infinitely adjustable.

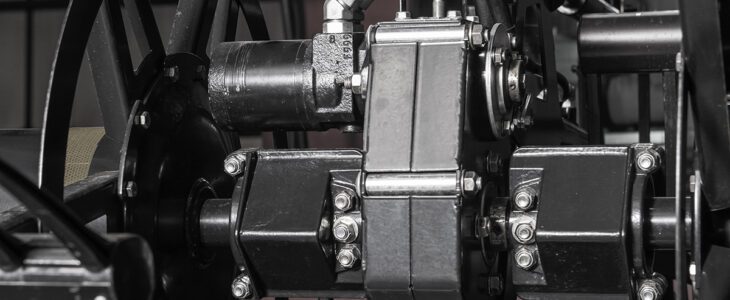

Reversible mechanical drive

The center drive reduces weight and provides more powerful cutting and feeding action.

Switch from flex to rigid mode

The switch from flex to rigid mode is made from the cab of your combine, at the push of a button.

The draper header you’ve been waiting for

In flex mode, the AirFLEX NXT will shave the ground, picking up more of your peas, lentils or soybeans. In rigid mode, the no-compromise cutterbar will race through taller crops like canola and cereals.

Only cutting in soybeans? There’s an AirFLEX NXT that’s optimized for you.

WHAT’S NEW & IMPROVED

Cab-Adjustable Skid Shoes

In flex mode, the skid shoes achieve a consistent stubble height of 0” to 8” across the width of the cutterbar and can be adjusted instantaneously from the cab of your combine.

Narrow Profile End Shield

A new 5” design replaces the 8”. The thinner end shield and crop divider design reduces flattening of crop and enhances manoeuverability along field borders and through row crops.

New Reel Drive

A new reel drive allows switching from standard to high torque with half the speed and double the torque.

Cross Auger

A larger 12” diameter hydraulic cross auger improves material flow from the drapers to the feed auger, adjusting for bulky and tangled crops like peas and mustard.

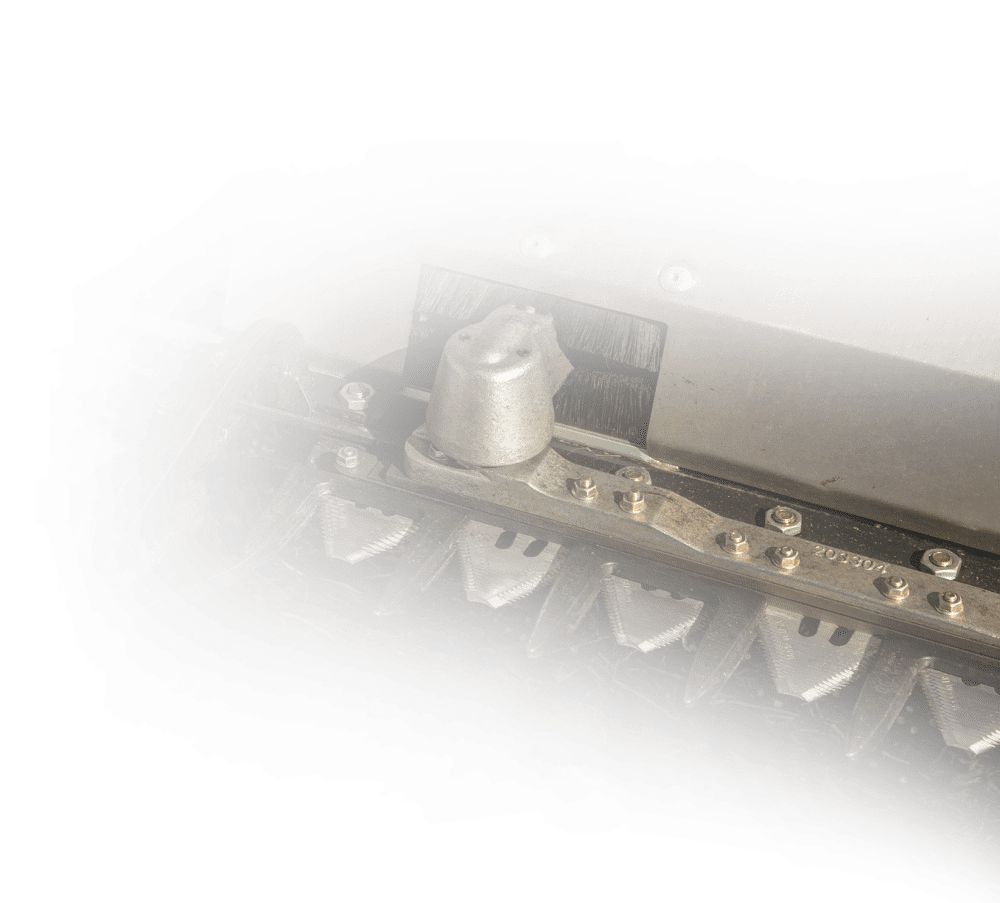

Low Profile Vertical Shear Design

The redesigned vertical shear features a thinner profile and a simpler design.

Improved Airbag Orientation

A new design applies a consistent force from the airbag to the cutterbar, allowing for better floatation throughout the full flex range and reducing wear along the cutterbar and skid shoes.

Transport Cart

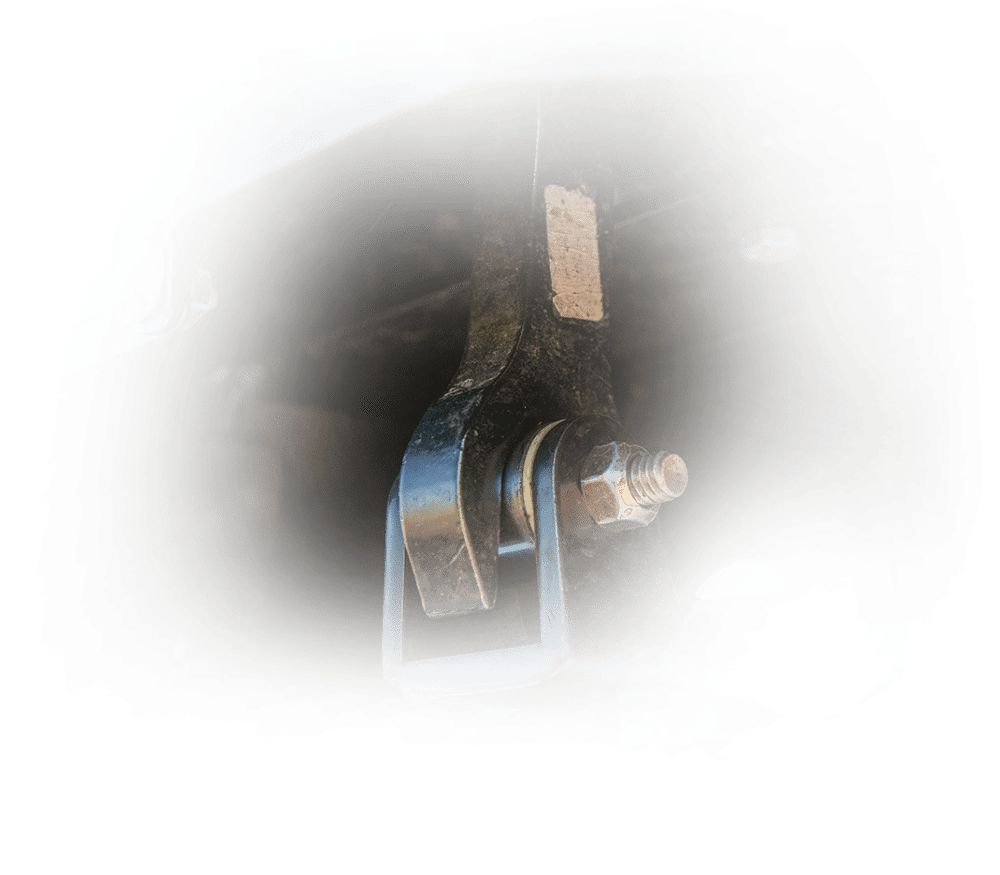

Upgrades to the transport system allow the transport cart lock pin to be engaged/disengaged from one easily accessible latch arm.

Improved Drive Shafts

An improved drive shaft quick coupler reduces play in the knife drive short shaft.